Machinery Manufacturing

Comprehensive process support for production of complex machinery and its equipment

Build superior machines with Etrust AMS

Etrust AMS is the result of research and development at Etrust and is tailored for the machinery industry, focusing on manufacturers of agricultural and forestry machinery. This independent software solution emphasizes production planning, facilitating a comprehensive flow of information throughout the production process and providing real-time visibility of events in manufacturing for foremen, technologists, planners, and management.

It is designed to connect with other systems via API interfaces, machines, and process equipment. The modularity allows for IoT connections to machines and equipment, as well as the implementation of digital twins for simulations and production optimizations. For more complex manufacturing needs, Etrust AMS is compatible with Siemens OpCenter for advanced scheduling and production planning.

Enhance your R&D Efficiency

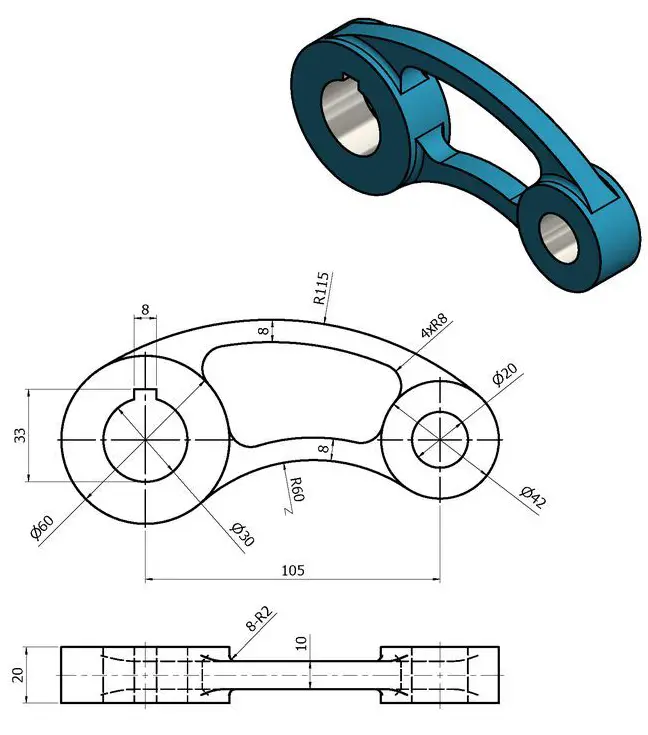

In the machinery manufacturing industry, Research and Development (R&D) departments rely on advanced CAD systems like SolidWorks to design and develop innovative machinery products. Etrust Advanced Manufacturing System (AMS) seamlessly supports this process by enabling the import and creation of products within a structured framework known as Bills of Materials (BOMs).

Our system empowers R&D teams and technologists to streamline their workflows, providing clear visibility and tracking throughout the entire product creation journey—from initial design and development to technological preparation, which is essential for the Workorder release process.

With Etrust AMS, technologists have easy access to all construction elements and plans, simplifying the application of technology to each product. This efficiency not only reduces errors in preparing technology BOMs but also ensures accuracy in determining the correct version of the plans and verifying that all required materials are utilized.

Take your manufacturing processes to the next level with Etrust AMS, where technology and innovation drive success in product development.

Track your Manufacturing Processes in Real-Time

Discover the power of our Manufacturing Execution System (MES)—a vital component of Etrust AMS designed to enhance the management and control of your production lines and collaboration with partners in real-time.

Our MES acts as a centralized information hub, streamlining production management while providing a seamless registration point for marking the start and end of individual operations. With integrated machine connectivity (IoT), you can optimize efficiency wherever it counts.

Elevate your manufacturing process and stay agile in today’s competitive landscape with Etrust AMS and MES - your key to smarter, faster, and more effective production management!

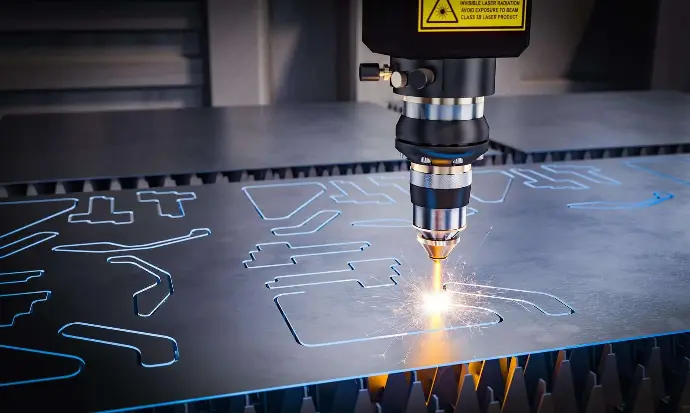

Streamline your Laser cutting process

One of the significant challenges in the machinery manufacturing industry is effectively controlling the laser cutting process. In serial machinery production, laser operators typically rely on predefined cutting templates that must be perfectly aligned with the workorder release process. Conversely, in project-based machinery manufacturing, operators often create laser cutting templates on-the-fly as they release each work order to the laser cutting software.

No matter your production method, Etrust AMS is here to enhance and support your operations. Our cutting-edge system connects seamlessly to your laser cutting machines, ensuring efficient management for both predefined templates and project-based manufacturing.

For serial production, Etrust AMS retrieves templates and monitors the products being processed in real time. For project-based manufacturing, it efficiently sends each individual workorder to your laser cutting machine, providing real-time production data that pairs perfectly with your workorders for accurate post-workorder calculations.

Empower your manufacturing process and boost your efficiency with Etrust AMS - your solution for a smarter, more connected laser cutting experience!

Elevate your Paintshop Operations with Etrust AMS

Etrust AMS revolutionizes the way you plan and manage your paintshop operations. Unlike other systems, Etrust AMS offers a unique approach to paintshop operations management that integrates seamlessly with our workorder release process. This powerful combination empowers you to manage your workorder release without making variations to your technological procedures.

For instance, in the machinery manufacturing industry, imagine a company that produces machinery components and semi-products using a make-to-stock model. It would be extremely inefficient to pre-paint those componets, because you would never have optimal components in correct color in your inventory. That's why Etrust AMS tackles this problem, when a sales order is placed, the system automatically defines the machine's color and determines the color for each associated component and creates corresponding paintshop plan.

Etrust AMS intelligently plans paintshop operations and efficiently calls bruto components from inventory, releasing workorders to the paintshop to ensure that semi-products are finished with painting and ready for assembly just in time.

Don’t compromise on efficiency! Enhance your production capabilities with Etrust AMS and ensure your paintshop operations are streamlined, precise, and perfectly timed for optimal machine assembly. Transform your manufacturing process today!

Some of the best machinery manufactures trust us!

Contact us for a personalized meeting