Etrust proizvodni inf. sistem

Machinery Manufacturing | Project-based Manufacturing | Make-to-stock | High-series Manufacturing | Laser cutting | Digital printing

Etrust PRIS – zasnovan za realne proizvodne procese

Etrust PRIS je proizvodni informacijski sistem, razvit na podlagi dolgoletnih izkušenj in raziskav v podjetju Etrust. Zasnovan je za podjetja z zahtevnimi proizvodnimi procesi – od strojegradnje in projektne proizvodnje do naročniške, serijske in tehnološko specializirane proizvodnje, kot sta laserski razrez in digitalni tisk.

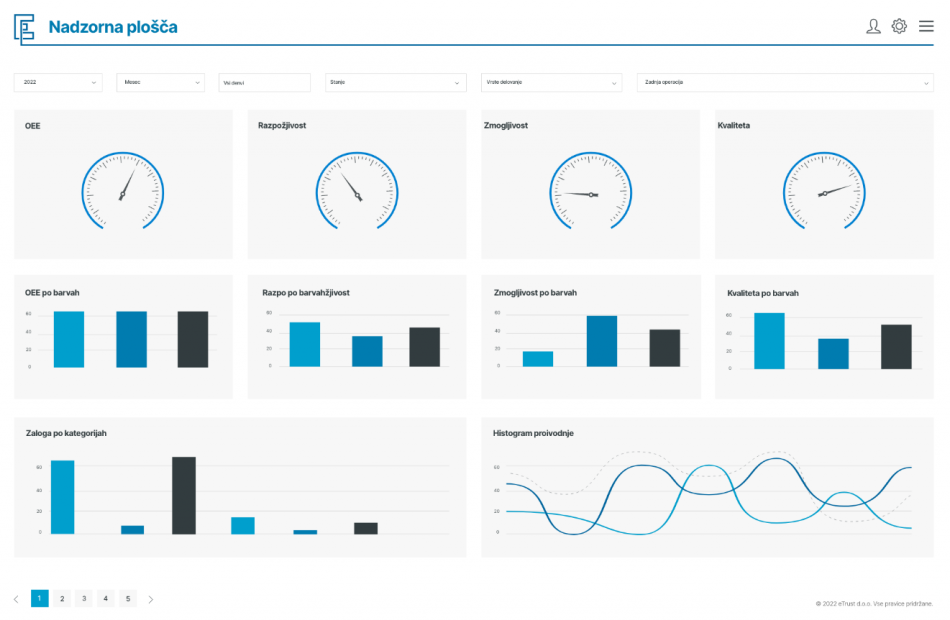

Proizvodnja, vodena s pravimi podatki

Etrust PRIS ne temelji zgolj na spremljanju proizvodnje, temveč na aktivnem vodenju proizvodnega procesa. Sistem povezuje konstrukcijske podatke, tehnologije, razpis proizvodnje in izvedbo v enoten proces, kjer vsi deležniki delujejo na isti, vedno aktualni podatkovni osnovi.

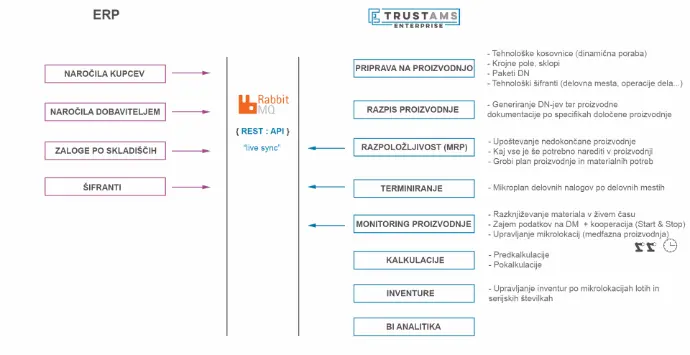

Odprta in modularna arhitektura

Etrust PRIS je zasnovan kot neodvisna in modularna programska rešitev, ki omogoča:

- integracijo z obstoječimi ERP in B2B sistemi,

- povezovanje z drugimi rešitvami prek API vmesnikov ali RabbitMQ,

- integracijo strojev in procesne opreme,

-

postopno uvajanje IoT povezav in digitalnih dvojčkov za simulacijo in optimizacijo proizvodnje.

Sistem se prilagaja vašemu okolju – ne obratno.

Enoten proizvodni informacijski sistem – ne skupek ločenih modulov

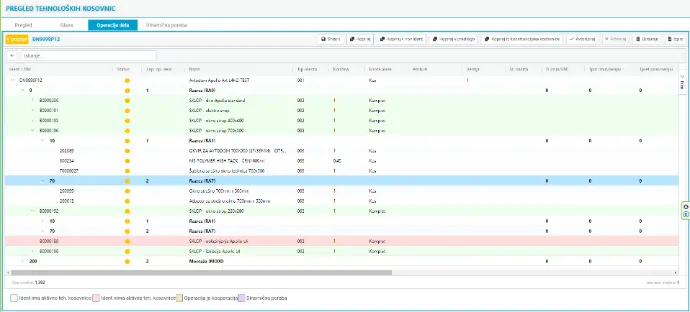

Namesto ločenih sistemov PRIS združuje ključne proizvodne funkcionalnosti v enoten okvir:

- upravljanje kosovnic in tehnologij,

- avtomatiziran razpis proizvodnje in generiranje delovnih nalogov,

- sledljivost medfazne proizvodnje,

- MES, evidenco delovenga časa in porabe materiala,

- planiranje in analitiko.

Vsaka funkcionalnost deluje v kontekstu celotnega procesa, ne izolirano.

Konstrukcijske kosovnice in tehnologije

Etrust PRIS povezuje konstrukcijske kosovnice in tehnologije v enoten, verzioniran sistem. Sprememba polizdelka ali postopka se samodejno prenese v vse nadrejene izdelke in razpis proizvodnje.

WOR

Workoder release systems manage the process of building and releasing workorders to the shop floor. Efficient workorder automation is crucial to maintaining balanced loads across various manufacturing stages.

MES – izvršilni del Etrust PRIS

MES v Etrust PRIS spremlja izvedbo delovnih nalogov v realnem času – z evidenco časa, porabe materiala in medfazne proizvodnje. Deluje kot izvršilni sloj sistema, ki temelji na pravilno pripravljenih podatkih.

MRP – material v kontekstu proizvodnje

Materialno planiranje, neposredno povezano s kosovnicami, tehnologijami in razpisom proizvodnje. MRP v Etrust PRIS zagotavlja, da so materiali na voljo takrat in tam, kjer jih proizvodnja dejansko potrebuje.

APS – planiranje v realnem okolju

APS systems optimize manufacturing planning by considering constraints such as material availablity, machine capabilitites and service leves. APS is essential for generating efficient production plans that minimize waste and maximize output.

WMS – mikrolokacijsko skladiščno poslovanje

Skladiščno poslovanje, povezano s proizvodnimi mikrolokacijami in delovnimi nalogi. Etrust PRIS omogoča sledljivost materiala in polizdelkov v realnem času.